Five-axis machining centers represent the pinnacle of CNC machining technology, offering unparalleled capabilities for manufacturing complex components with high precision. This guide delves into their structure, benefits, and key selection criteria.

What is a Five-Axis Machining Center? An In-Depth Look at Its Structure

A five-axis machining center is an advanced CNC machine tool that operates along five distinct axes: three linear (X, Y, Z) and two rotational (A and C). This configuration enables simultaneous movement along all axes, allowing for the processing of intricate geometries in a single setup.

The rotational axes are typically configured in two ways:

The A-axis rotates around the X-axis, with a common working range of 30 to 120 degrees.

The C-axis rotates around the Z-axis, providing full 360-degree rotation.

This combination allows the cutting tool to access five sides of a workpiece in one operation, eliminating the need for multiple repositioning. The high-precision rotational axes, often with a resolution of 0.001 degrees, enable machining at any angle and the production of complex contoured surfaces, bores, and inclined surface.

Key Advantages of Five-Axis Machining Centers

1,Enhanced Capability for Deep and Steep Cavities

The rotational movement of the workpiece or spindle head optimizes tool orientation, preventing collisions between the tool, holder, and cavity walls. This reduces tool vibration and breakage, improves surface finish, and increases tool life.

2,Reduced Setup Time and Costs

Complex parts can be completed in a single clamping, eliminating the time, potential for error, and expensive fixtures associated with multiple setups.

3,Unmatched Geometric Freedom

These machines can produce highly complex parts—such as those with off-axis holes, cavities, and tapers—that are impossible to manufacture using traditional 3-axis methods.

4,Improved Efficiency and Surface Quality

The use of shorter, more rigid tools is possible, which increases stability and allows for higher feed rates. This leads to faster cycle times and superior surface finish, often without the need for secondary finishing.

Machining Types in Five-Axis Applications

1. Point Contact Machining

This common method uses a spherical tool (e.g., a ball-nose end mill or grinding wheel) to contact the workpiece at a single point. Its key advantage is the ability to adapt to surfaces with complex curvatures. While programming is relatively simple, the near-zero cutting speed at the very center of the tool can lead to poorer cutting conditions, lower efficiency, and reduced accuracy compared to other methods.

2. Face Contact Machining

This method employs the face of a tool (e.g., in face milling or grinding) for material removal. The higher cutting speeds and larger feed rates result in superior machining efficiency and accuracy. However, its application is limited by the tool’s specific shape and is best suited for flatter, convex surfaces.

3. Line Contact Machining

An area of ongoing research, this technique involves contact along a line (e.g., using a conical or cylindrical tool or belt grinding). It promises high machining accuracy due to excellent cutting speeds and high efficiency from the larger contact area. Development is focused on applying this method to arbitrary free-form surfaces.

How to Choose a Five-Axis Machining Center: 6 Critical Factors

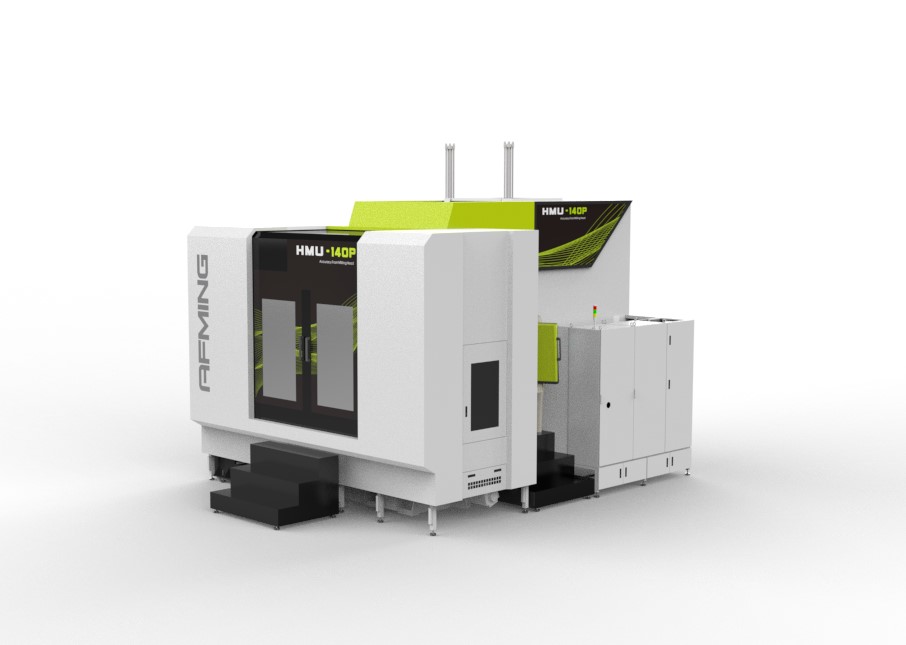

1. Machine Structure and Design

The fundamental design (e.g., table-table, head-head, or mixed) dictates the machine’s rigidity, accuracy, stability, and overall performance potential. The choice depends on the size and type of workpieces you intend to process.

2. Rotational Axis Accuracy

The precision of the B and C axes is paramount. Look for high-resolution encoders and demand specifications in arc-seconds (“), not just degrees. For instance, a common specification for a high-end machine is a positioning accuracy of ±3 arc-seconds.

3. Collision Prevention Technology

Beyond software simulation, advanced machines offer real-time CSG (Contact Sensor Guard) functionality that provides a physical safety buffer, preventing crashes even during manual operation.

4. Automatic Calibration

Thermal changes and environmental factors can shift the machine’s rotational center. Probe-based automatic calibration systems are essential for periodically correcting these deviations and maintaining micron-level accuracy (< 4 µm) across all operating modes.

5. Simultaneous Motion Accuracy

The true test of a five-axis machine is its simultaneous accuracy. This is a result of its geometric accuracy, dynamic performance, CNC system capabilities (like RTCP and look-ahead), and advanced error compensation technologies. This must be verified through practical tests like the NAS 979 cone test or S-part trial cut.

6. Process Support and Expertise

The machine’s performance is only as good as the software and programming behind it. Ensure the manufacturer provides strong technical support, training, and proven machining strategies (e.g., for profile cutters) to maximize your investment.

Conclusion

Five-axis machining centers are indispensable in high-tech industries like aerospace, medical, and energy, enabling the production of critical components like impellers, turbine blades, and complex prosthetics. Understanding their capabilities and the factors influencing their performance is the first step toward leveraging their full potential to gain a competitive manufacturing advantage.